Cortec® Corporation is committed to providing world class corrosion solutions for industries across the globe. As the global leader in innovative, environmentally responsible VpCI® and MCI® corrosion control technologies, Cortec® seeks to deliver cost-effective, user-friendly integrated solutions for corrosion problems in packaging, metalworking, construction, electronics, oil and gas, and many other industries.

Cortec’s foundation has been built around a commitment to our environment. We continually strive to improve the performance of our products and our processes while reducing their environmental impact. Cortec’s MCI® products not only provide corrosion protection to metals on both new and existing structures, they benefit our environment.

We have admixtures derived from renewable resources such as corn, soy based curing compounds, water-based coatings and repellants, and many of our products also meet NSF Standard 61 approval for use in structures holding potable water.

NEW PERSPECTIVES IN CORROSION PROTECTION FROM MCI®

What is Cortec MCI Technology?

Cortec Corporation’s patented MCI (Migrating Corrosion Inhibitor) Technology protects reinforcing metal in concrete from corrosion. Often, corroding rebar in deteriorating concrete is the cause of costly repairs, financial losses, injuries, and even deaths, but Cortec has the corrosion solution. MCI greatly extends the service life of new and existing structures by proactively delaying the onset of corrosion and keeping rates low after initiation. Cortec MCI products maintain structural integrity, rehabilitate vulnerable structures, and alleviate environmental concerns.

How does MCI Technology Work?

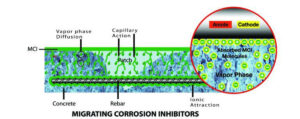

MCIs are based on amine technology (amine alcohols and amine carboxylates). They are classified as mixed inhibitors, meaning they affect both anodic and cathodic portions of a corrosion cell. MCI® is applied in many forms including as a concrete admixture or a topical treatment. It moves as a liquid through the concrete matrix via capillary action and migrates in a vapor phase throughout the concrete pore structure. When MCI® comes in contact with embedded metals, it has an ionic attraction to it and forms a protective molecular layer. This film prevents corrosive elements from further reacting with the reinforcement and also reduces existing corrosion rates, greatly extending concrete service life.

(Click on images to enlarge)

Durability and Sustainable Construction

Sustainable construction has become a goal for owners across the globe. While much attention has gone to reducing cement use and minimizing power and water consumption, an often overlooked aspect is the durability and service life of the final structure. However, this is undoubtedly one of the key parameters influencing structural sustainability. By using MCI in severely corrosive environments, structures will have a stronger resistance to corrosion and therefore possess greater durability. Increased durability will mean fewer repairs, greater structural integrity, and a longer service life, all leading to greater sustainability. MCI is made from a renewable raw material, enabling users to earn certain LEED credits. It is an excellent addition to building projects around the world seeking to meet sustainability standards such as the Estidama Pearl Rating System and BREEAM.

Concrete Admixtures

Time and time again, MCI® corrosion inhibitor products are shown to outperform the competition. Other admixtures rely on pore blockers or are limited by a chloride threshold. In contrast, MCI® specialty admixtures added to concrete work independently of chlorides, protect even when cracks occur, and can actually delay setting time of concrete for better workability. They do not affect the physical properties of concrete mixtures when used at the recommended dosage rates.

MCI-2005

MCI-2005 is a water-based, organic, corrosion inhibiting admixture for the protection of metallic reinforcement in concrete structures. When incorporated into concrete, MCI-2005 migrates towards reinforcement. Once there, it forms a monomolecular layer that inhibits the corrosion reaction on both anodic and cathodic components of the corrosion cell. This effect can be quantified by the increased critical chloride threshold and subsequent reduction in corrosion rate.

Product Data Sheet

MCI Mini-Grenades

Mini MCI Grenades consist of Migrating Corrosion Inhibitors (MCI) packaged in water-soluble PVA bags. Mini MCI Grenades are very convenient to use. Mini MCI Grenades are ideal for repair mortars- -one Mini Grenade protects 0.4-0.6 ft3 (0.015 m3). The grenade dissolves easily when in contact with water in the concrete mix. During mixing the bag will completely dissolve and the MCI compounds will begin to disperse into the mix. The MCIs protect reinforcing steel, galvanized steel, and other metals embedded in concrete from corrosion induced by carbonation, chloride, and atmospheric attack. When incorporated into the concrete mix the MCIs form a corrosion inhibiting protective layer on metals. When used with repair mortars and grouts, MCIs will migrate toward the rebars providing effective corrosion protection.

Product Data Sheet

Restoration

MCI is important for ensuring the longest possible lifespan of concrete restoration projects. MCI not only slows the rate of corrosion begun in deteriorating structures, but also protects against the troublesome ring anode/insipient anode effect that often follows concrete repairs. MCI is ideal and convenient to add to concrete repair mixtures and migrates through adjacent areas after application to protect embedded reinforcement. MCI is also available as a passivating grout for use on exposed rebar, or as a topical treatment to existing surfaces.

MCI Mini-Grenades

Mini MCI Grenades consist of Migrating Corrosion Inhibitors (MCI) packaged in water-soluble PVA bags. Mini MCI Grenades are very convenient to use. Mini MCI Grenades are ideal for repair mortars- -one Mini Grenade protects 0.4-0.6 ft3 (0.015 m3). The grenade dissolves easily when in contact with water in the concrete mix. During mixing the bag will completely dissolve and the MCI compounds will begin to disperse into the mix. The MCIs protect reinforcing steel, galvanized steel, and other metals embedded in concrete from corrosion induced by carbonation, chloride, and atmospheric attack. When incorporated into the concrete mix the MCIs form a corrosion inhibiting protective layer on metals. When used with repair mortars and grouts, MCIs will migrate toward the rebars providing effective corrosion protection.

Product Data Sheet

Surface Treatments

Surface Treatment: Pure Inhibitors

MCI can be applied to existing structures as a surface treatment that reduces corrosion rates. This surface treatment is designed to penetrate into and migrate through cementitious materials to reach and protect embedded reinforcing metal. MCI surface treatments can be applied on vertical and overhead surfaces, as well as horizontal surfaces. MCI pure inhibitors do not contain water repellants but provide extra-strength corrosion protection to embedded rebar through a powerful dose of MCI inhibitors. These straight inhibitors work at rebar level to effectively protect reinforcing metal from corrosive elements with or without the use of sealers.

Surface Treatment: Water Repellant MCI

MCI sealers combine water repellency with the added protection of Migrating Corrosion Inhibitors. These MCI surface treatments seal surface pores to block carbonation and protect against the ingress of water, chlorides, and other aggressive contaminants. Below the surface, MCI® penetrates to the depth of embedded metallic reinforcement to form a protective monomolecular layer on the surface of the rebar. This protective layer delays the onset of corrosion and reduces corrosion rates after initiation, greatly extending the service life of structures.

MCI-2020

MCI-2020 is a surface applied, migrating corrosion inhibitor designed to penetrate through cementitious materials including concrete, mortar, and limestone. MCI-2020 migrates in both liquid and vapor (gas) phases through the pore structure, forming a protective, molecular layer on embedded reinforcement. MCI-2020 provides corrosion protection against carbonation, chlorides, and other contaminants. MCI-2020 V/O is a high viscosity version of MCI-2020 which is specifically designed for vertical and overhead applications.

Product Data Sheet

MCI-2018

MCI-2018 is a 100% silane concrete sealer containing time-proven Migrating Corrosion Inhibitors (MCI). MCI- 2018 penetrates deep into concrete providing corrosion protection to reinforcing steel from existing water and chloride ions, or other contaminants. MCI-2018 also provides water repellency by chemically reacting with the cementitious substrate under proper application, decreasing the ingress of additional aggressive materials.

MCI-2018 V/O is particularly formulated for application on vertical surfaces. MCI-2018 FD and MCI-2018 V/O FD both contain a red fugitive dye to aid in uniform application and job inspection. The color will stay on concrete for about 7 days but fade in about 30 days, depending on sunlight (UV) exposure.

MCI-2018 UV contains a UV dye to confirm applications without affecting the appreance of the surface.

MCI-2018 and MCI 2018 VO are available with a permenant Red or Blue stain.

Product Data Sheet

Specialty Products

Specialty Products

Cortec offers the flexibility of specialty products for multiple aspects of the construction industry. Many of these products are a result of customer suggestions that meet specific end user needs. In addition to Migrating Corrosion Inhibitors, Cortec offers products for concrete cleaning, rebar storage, and rust conversion.

Cleaning Oil Stains from Concrete

MCI-2061 is a powerful natural cleaner that safely and effectively cleans oil stains on concrete. Microorganisms in the cleaner remain inactive until the product is applied to pre-wetted concrete and rinsed. Microorganism spores that remain after rinsing continue to work to degrade residual stains from the concrete.

Cleaning Organic Waste

MCI-2062 is a pre-stabilized liquid bacteria and free enzyme cleaner concentrate available in either 10X or 20X format. This product can be used for odor control as well as for cleaning a wide variety of organic wastes such as grease, fats, oils, starches, proteins, and cellulose. Rinse-water containing will also provide residual cleaning downstream

MCI-2062 Product Data Sheet

Rust Converting Primer

CorrVerter is a water-based primer recommended for application on rusty or poorly prepared steel surfaces where corrosion protection is required and good surface preparation is difficult to achieve. CorrVerter penetrates rust, eliminates rust, and stops further rusting.

MCI CorrVerter

CorrVerter is a water-based primer recommended for application to rusty or poorly prepared steel surfaces where further corrosion protection is required and good surface preparation is difficult to achieve. CorrVerter is formulated to penetrate rust, eliminate rust, penetrate to the bare metal, and stop further rusting.

CorrVerter contains a novel chemical chelating agent that modifies the surface rust into a hydrophobic passive layer. CorrVerter combines the above mentioned chelating agent with a high solids waterborne latex with extremely low water vapor permeability. The combination of the active chelating agent with a film-forming latex, thickeners and dispersant offers a unique formulation for a primer with excellent protection against re-rusting.

CorrVerter does not contain tannic or phosphoric acids, provides long-term corrosion protection for poorly prepared substrates, and can be topcoated with solvent-based and water-based paints with no bleeding.

Product Data Sheet

MCI-2061

MCI-2061 is a powerful cleaner that safely and effectively cleans oil stains on concrete. This hard surface cleaner is unique because it combines powerful cleaning chemistry with microorganisms capable of biodegrading hydrocarbons, such as those found in oil, diesel, and other materials that stain concrete.

MCI-2061 is formulated with biodegradable surfactants and is used like other hard-surface cleaners. During the initial application the cleaning action is simply due to the surfactant component of the product. The microorganisms in MCI-2061 are preserved bacterial spores that remain inactive until MCI-2061 is used. The spores then germinate into vegetative, or active, microorganisms when MCI- 2061 is applied to pre-wetted concrete and rinsed according to use instructions. Spores that remain after rinsing germinate and work to degrade residual hydrocarbon constituents of the stain that weren’t removed in the initial cleaning process. Spores that are rinsed away may also germinate and work to purify the rinse water.

MCI-2061 is an environmentally friendly alternative that eliminates the need for harsh solvent-based and alkaline cleaners. With biodegradable surfactants, a neutral pH, no solvents and virtually no VOC’s (<1%) MCI-2061 makes it easy to maintain a cleaner and healthier facility. Product Data Sheet

MCI-2062

MCi-2062 is a multi-purpose bio-enzyme blend that serves as a concentrated source of synergistic bacteria strains and free hydrolytic enzymes capable of digesting organic waste. It can be used for odor control and for cleaning a wide variety of organic wastes such as grease, fats, oils, starches, proteins, and cellulose.

MCI-2062 should always be mixed for a minimum of 20 minutes prior to batch formulation. 10X concentrate can be diluted 1:9 parts in DI water. 20X concentrate can be diluted 1:19 parts in DI water.