Pultrall V-Rod Fiberglass Rebar

Revolution in Concrete Construction – The Solution for Corrosion

Pultrall is a pioneer in non-metallic concrete reinforcement solutions and an undisputed leader in the number of road infrastructure project completions in North America. The technology of reinforced concrete is facing a serious degradation problem in structures due to the corrosion of steel rebar. Fibre-reinforced polymer (FRP) rebar has proven to be the solution. Lightweight, corrosion resistant, and offering excellent tensile strength and high mechanical performance, V•ROD rebar is installed much like steel rebar, but with fewer handling and storage problems.

Thanks to V•ROD, builders and owners of structures can take advantage of a major evolution in reinforced concrete technology. This means:

• More secure structures

• Non-existent corrosion

• Reduced life cycle cost of 15 to 30%

The advantages of V•ROD rebar are backed by years of testing and actual field results in the most demanding conditions. From now on, limitations will lie with the concrete, and not the reinforcement.

V-Rod Raises the Bar

Corrosion Rebar

V•ROD rebar does not rust, even in the harshest environments. It does not react to salt, chemical products or the alkaline present in concrete.

Superior Tensile Strength

V•ROD rebar produced by pultrusion offers a tensile strength up to twice that of steel.

Thermal Expansion

V•ROD rebar offers a level of thermal expansion comparable to concrete due to its 80% silica content.

Electrical & Magnetic Neutrality

V•ROD rebar does not contain any metal; it will not cause any interference in contact with strong

magnetic fields or when operating sensitive electronic instruments.

Simplified On-site Management

V•ROD rebar can be delivered at the right time and in the exact quantity needed at the site. Various specifications such as the length, angles or bends of special sections are prepared in the plant.

Lightweight

V•ROD rebar is 4 times lighter than steel rebar. It is much easier to handle, and in most cases, one truck load will be sufficient to supply the rebar even for an entire project.

Thermal Insulation

V•ROD rebar does not create a thermal bridge within structures.

Increased Safety & Savings

Savings on Life Cycle Costs

Given the present value for total costs of maintenance and demolition, using V•ROD technology represents a savings of 45 to 60%.

Given the present value of the overall life cycle cost, using V•ROD

technology represents a savings of roughly 15 to 25%.

If we add unknown factors such as the fact that fragile epoxy coating

may be compromised due to impact when installing rebar, the savings

provided by using FRP increases from 15 to 30%.

Construction Savings

V•ROD rebar allows costs to be eliminated related to the use of expensive membranes.

It is possible to use conventional concrete instead of low permeability concrete with added corrosion inhibitors.

Reduced weight allows for the handling of more rebar at the same time and reduces installation time.

Increased Safety for Owners & Users

V•ROD rebar is manufactured according to set standards, has been approved by ISIS Canada and is included in CSA design standards.

Standard specifications are now available to engineering firms for quality control of projects, including independent on-site inspection.

Installation methods in concrete have been standardized in accordance with those of steel.

V-Rod Applications

TRANSPORT

Bridges, barrier walls and decks

TUNNELS

Diaphragm walls (soft eye)

MINING

Rock bolts and structures

MARINE INSTALLATIONS

Wharfs, sea walls and wave breakers

WATER TREATMENT

Drinking water and wastewater

INDUSTRIAL APPLICATIONS

Aluminum smelters

CIVIL ENGINEERING

Retaining walls

ARCHITECTURAL

Architectural/decorative concrete elements

BUILDING

Multi-storey parking garage, balconies and magnetic resonance imaging equipment rooms

Technical Data Sheets

Direct Comparison - Steel & V-Rod

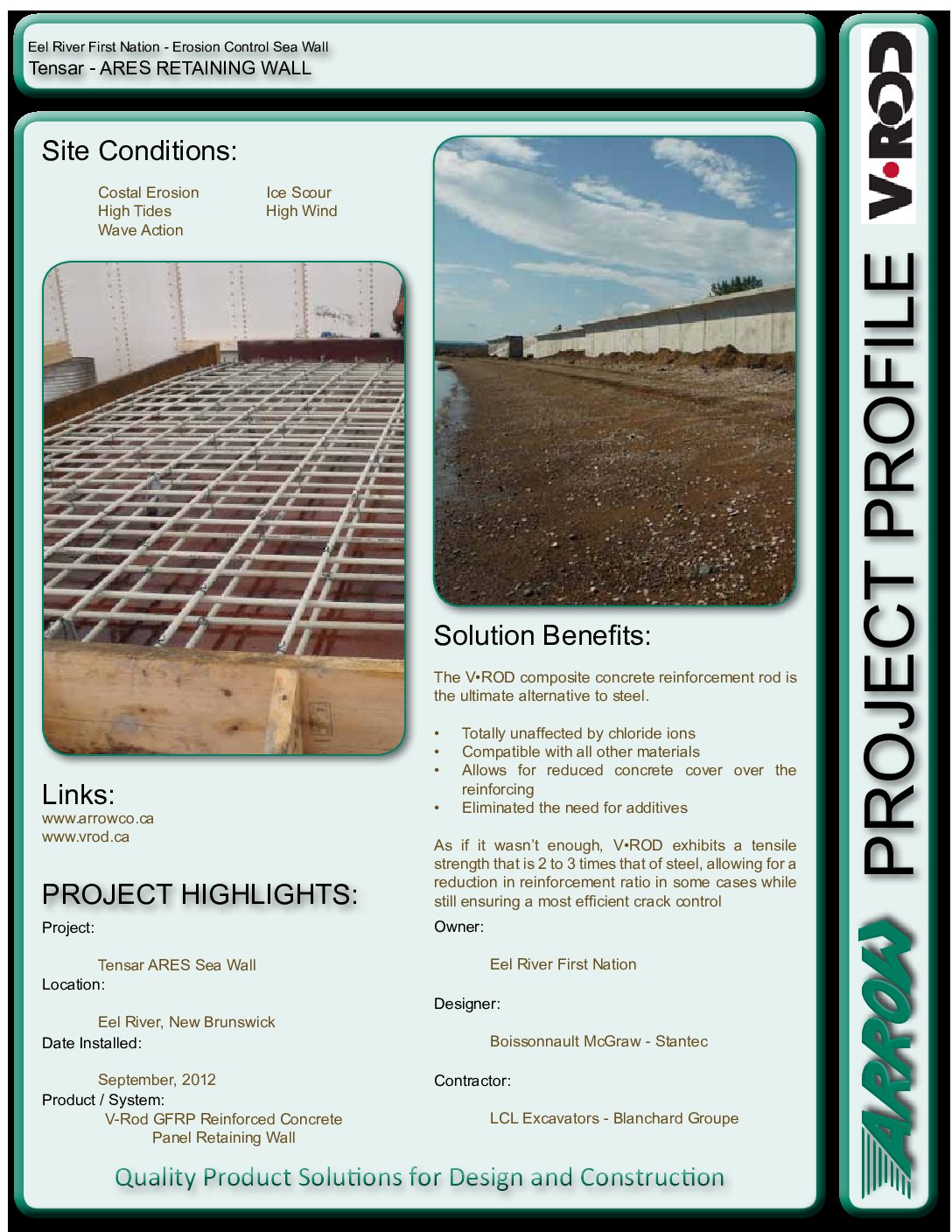

Eel River Sea Wall - New Brunswick

Eel River Sea Wall – NB

Product / System: V-Rod GFRP Reinforced Concrete Panel Retaining Wall

Rattle Brook Bridge - Newfoundland

Rattle Brook Bridge – NL

Product / System: FRP Re-Bar